Lab Description

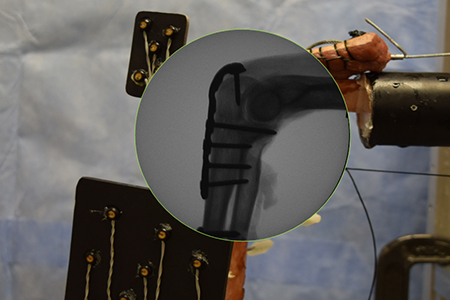

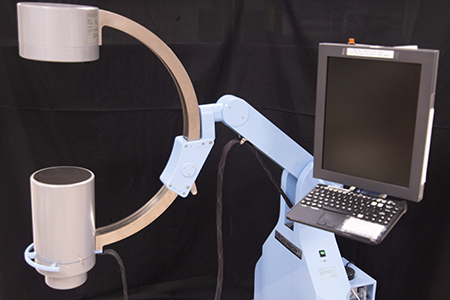

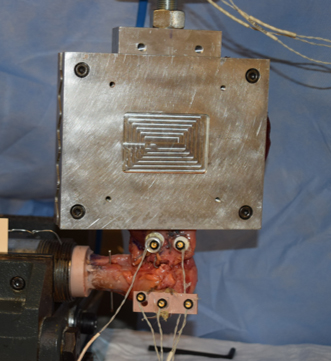

The Biomechanics Research Laboratory houses state-of-the-art, research grade, motion tracking, materials testing, and bio-robotic testing equipment. We undertake biomechanical testing and investigations concerning effects of various orthopedic interventions and implantable devices on musculoskeletal biomechanics, implant strength and fracture fixation.

The biomechanics team is dedicated to developing innovative and rigorous testing strategies for evaluating orthopedic devices that result in overall improved quality of life with the least risk of potential injury for patients. The team also leads the “Helping Hands” charitable activities of the Foundation.